Schritt für Schritt Videoanleitung:

Das Problem Ins Auge stechende, durchlöcherte, großflächig-rostbefallene Karosserie. Keiner will mehr damit fahren aber wegwerfen will ihn auch keiner da das Auto technisch noch ganz gut in Schuß ist.

Achtung: Rostlöcher an tragenden Teilen wie Einstiegsholmen, Unterbodenverstrebungen und Längsträgern dürfen auf keinen Fall mit Spachtelmasse ausgeglichen werden. Diese Schäden müssen unbedingt vom Fachmann verschweißt werden.

Schwierigkeit:

anspruchsvoll

anspruchsvoll

Zeitaufwand:

5-8h

5-8h

Kosten:

200€

200€

Ersparnis:

1000€

1000€

Zusätzliches Werkzeug:

Schleifer Handwerkzeug

Schleifer Handwerkzeug

– Reparatur-Set für Sie: Film Set Rost und Rostlöcher reparieren

– Reparatur-Set für Sie: Film Set Rost und Rostlöcher reparierenUnd so geht`s:

Rost entfernen

Weg mit dem Rost und einfach selber die Karosserie reparieren.

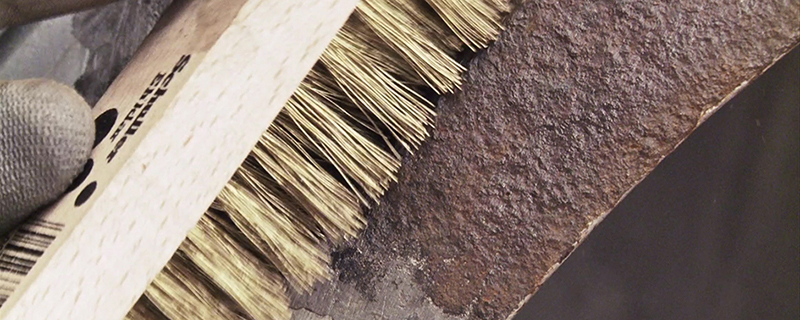

Rost, abstehende, lose Blechteile und absplitternde Lackschichten vollkommen entfernen.

Trockenschleifpapier – grobe Körnung P 60 – um einen Schleifklotz wickeln und die Roststellen großflächig blank schleifen.

Da darf kein bisschen Rost am Auto mehr zu erkennen sein. Wo vorher Rost war, muss es jetzt blitzeblank glänzen!

Danach mit Silikonentferner die Stelle sehr gründlich reinigen.

Rost, abstehende, lose Blechteile und absplitternde Lackschichten vollkommen entfernen.

Trockenschleifpapier – grobe Körnung P 60 – um einen Schleifklotz wickeln und die Roststellen großflächig blank schleifen.

Da darf kein bisschen Rost am Auto mehr zu erkennen sein. Wo vorher Rost war, muss es jetzt blitzeblank glänzen!

Danach mit Silikonentferner die Stelle sehr gründlich reinigen.

Roststellen absolut blank schleifen – Es darf kein Rost mehr zu sehen sein

Kitten

Auf die blitzblanke, tadellos geschliffene und mit Silikonentferner gereinigte Stelle kann jetzt Faserkitt aufgetragen werden.

Faserkitt (Spachtelmasse mit Polyesterfäden) haftet super am Metall und ist aufgrund der feinen Fasern in sich stabil.

Und so wird’s gemacht: Faserkitt auf ein Stück Karton streichen und Härter dazugeben. Die richtige Dosierung ist wichtig. Wenn Sie zuviel Härter verwenden, zieht der Kitt zu schnell an und kann nicht mehr verarbeitet werden, nehmen Sie zu wenig, härtet er nicht aus. Wie’s richtig gemacht wird, zeigt Ihnen Max im Film.

Die Spachtelmasse großzügig und großflächig auf die durchlöcherte Fläche streichen.

Faserkitt (Spachtelmasse mit Polyesterfäden) haftet super am Metall und ist aufgrund der feinen Fasern in sich stabil.

Und so wird’s gemacht: Faserkitt auf ein Stück Karton streichen und Härter dazugeben. Die richtige Dosierung ist wichtig. Wenn Sie zuviel Härter verwenden, zieht der Kitt zu schnell an und kann nicht mehr verarbeitet werden, nehmen Sie zu wenig, härtet er nicht aus. Wie’s richtig gemacht wird, zeigt Ihnen Max im Film.

Die Spachtelmasse großzügig und großflächig auf die durchlöcherte Fläche streichen.

Faserkitt auftragen, trocknen lassen und schleifen

Schleifen Nach 30 Minuten ist der Kitt ausgehärtet und Sie können mit grobem Schleifpapier den überflüssigen Kitt trocken abschleifen und so die ursprüngliche Form der Karosserie wieder herstellen.

Alles, was nicht grundiert und lackiert werden soll, wieder vor Sprühnebel schützen!

Dazu nehmen Sie einfach Abdeckpapier und Abdeckband (siehe Film).

Alles, was nicht grundiert und lackiert werden soll, wieder vor Sprühnebel schützen!

Dazu nehmen Sie einfach Abdeckpapier und Abdeckband (siehe Film).

Feinarbeit Nachdem alles plan geschliffen ist, gleichen Sie noch bestehende Krater und Schleifspuren mit Füller, bzw. Spritzspachtel aus.

Die Spraydose lange und kräftig schütteln, bis sich die Komponenten in der Dose gut vermischt haben (ca. 5 min). Die kleine Kugel in der Dose muss sich leicht und locker bewegen.

Auf die Dose kommt der Handgriff. Dieser funktioniert wie eine Spritzpistole und erleichtert die Arbeit enorm.

Die Spraydose lange und kräftig schütteln, bis sich die Komponenten in der Dose gut vermischt haben (ca. 5 min). Die kleine Kugel in der Dose muss sich leicht und locker bewegen.

Auf die Dose kommt der Handgriff. Dieser funktioniert wie eine Spritzpistole und erleichtert die Arbeit enorm.

Achtung:

Grundierung, Füller und Lacke sind zwar laut Herstellerfirmen ungefährlich, jedoch sicher nicht für die Lunge bestimmt – also unbedingt Schutzmaske tragen!

Grundierung, Füller und Lacke sind zwar laut Herstellerfirmen ungefährlich, jedoch sicher nicht für die Lunge bestimmt – also unbedingt Schutzmaske tragen!

Profi Tipp:Leichter und schneller geht’s mit einer Schleifmaschine oder Akkubohrmaschine mit Aufsatz. Das funktioniert super, macht mehr Spaß und spart enorm viel Zeit. Drei Minuten mit dem Schleifer ersparen 20 Minuten mühevoller Handarbeit. Schützen Sie alle Teile, die nicht geschliffen werden sollen, mit Abdeckband.

Profi Tipp:Leichter und schneller geht’s mit einer Schleifmaschine oder Akkubohrmaschine mit Aufsatz. Das funktioniert super, macht mehr Spaß und spart enorm viel Zeit. Drei Minuten mit dem Schleifer ersparen 20 Minuten mühevoller Handarbeit. Schützen Sie alle Teile, die nicht geschliffen werden sollen, mit Abdeckband.Grundieren Jetzt in mehreren dünnen Schichten (3 – 5) den Füller aufsprühen.

Zwischen den Spritzgängen 2 – 3 Minuten ablüften lassen.

Der ideale Spritzabstand beträgt 30 cm, die Idealtemperatur 15 bis 20 Grad.

30 Minuten nach dem letzten Spritzgang ist der Füller ausgehärtet und es kann mit Wasserschleifpapier (P500), Schwamm und einen Eimer voll Wasser (siehe Film) der überschüssigen Füller abgeschliffen werden.

Sorgfältiges Arbeiten ist hier ganz wichtig, es müssen alle Unebenheiten plan geschliffen sein.

Gefühl ist angesagt! Nicht auf Kitt oder Blech durchschleifen, sonst müssen diese Stelle wiederum grundiert werden.

Zwischen den Spritzgängen 2 – 3 Minuten ablüften lassen.

Der ideale Spritzabstand beträgt 30 cm, die Idealtemperatur 15 bis 20 Grad.

30 Minuten nach dem letzten Spritzgang ist der Füller ausgehärtet und es kann mit Wasserschleifpapier (P500), Schwamm und einen Eimer voll Wasser (siehe Film) der überschüssigen Füller abgeschliffen werden.

Sorgfältiges Arbeiten ist hier ganz wichtig, es müssen alle Unebenheiten plan geschliffen sein.

Gefühl ist angesagt! Nicht auf Kitt oder Blech durchschleifen, sonst müssen diese Stelle wiederum grundiert werden.

Grundierung aufsprühen und mit feinem Schleifpapier plan schleifen

Lackieren Ist die Grundierung aufgetragen, trocken (nach ca. 20 min) und geschliffen, kommt mit dem Reparaturlack bzw. Lackspray endlich Farbe ins Spiel!

Den Lackspray 5 Minuten kräftig schütteln, bis die Kugel hörbar anschlägt und alles gut vermischt ist. Handgriff aufstecken und in mehreren Schichten dünn lackieren.

Der ideale Spritzabstand beträgt 30 cm, die Idealtemperatur 15 bis 20 Grad.

Achtung! Nicht zuviel auf einmal aufsprühen, sonst gibt es Tränenbildung des ablaufenden Lackes… Im Film zeigt Max Schritt für Schritt, wie’s richtig gemacht wird.

Den Lackspray 5 Minuten kräftig schütteln, bis die Kugel hörbar anschlägt und alles gut vermischt ist. Handgriff aufstecken und in mehreren Schichten dünn lackieren.

Der ideale Spritzabstand beträgt 30 cm, die Idealtemperatur 15 bis 20 Grad.

Achtung! Nicht zuviel auf einmal aufsprühen, sonst gibt es Tränenbildung des ablaufenden Lackes… Im Film zeigt Max Schritt für Schritt, wie’s richtig gemacht wird.

Klarlack – Decklack Nach ca. 30 min. Trocknungszeit kommt der Klarlack über die Lackschicht.

Auch den Klarlack wieder gut schütteln und in mehreren Schichten (es sollten mindestens 5 sein) dünn auftragen und nach jedem Spritzgang ablüften lassen.

Der Klarlack schützt die Metallic-Teilchen vor Oxidation, er lässt den Lack glänzen und ist als Schutzschicht unbedingt notwendig.

Achtung! Bei Unilacken ist kein Klarlack erforderlich. Bei Unsicherheit entweder e-mail an max@dasauto.at oder die Hotline anrufen (+43 (0) 3687 24515 während der Geschäftszeiten).

Auch den Klarlack wieder gut schütteln und in mehreren Schichten (es sollten mindestens 5 sein) dünn auftragen und nach jedem Spritzgang ablüften lassen.

Der Klarlack schützt die Metallic-Teilchen vor Oxidation, er lässt den Lack glänzen und ist als Schutzschicht unbedingt notwendig.

Achtung! Bei Unilacken ist kein Klarlack erforderlich. Bei Unsicherheit entweder e-mail an max@dasauto.at oder die Hotline anrufen (+43 (0) 3687 24515 während der Geschäftszeiten).

Fast Fertig Von außen ist Ihr Auto jetzt wieder in Topform, aber auf der Innenseite der blank geschliffenen Stellen ist das Blech nun anfällig für neuen Rost.

Darum müssen Sie diesen Bereich unbedingt konservieren.

Sehr gute Ergebnisse erzielen Sie dabei mit Seilfett. Seilfett ist die einfache, ideale Lösung für Konservierung und Hohlraumschutz und als Spray in der 1-Liter Eurodose und im 5-Liter Gebinde im Shop erhältlich.

Nach ca. 1 Stunde Trockenzeit ist der Klarlack hart genug, um das Abdeckpapier zu entfernen.

…und – Voila! Das Ergebnis kann sich sehen lassen!

Darum müssen Sie diesen Bereich unbedingt konservieren.

Sehr gute Ergebnisse erzielen Sie dabei mit Seilfett. Seilfett ist die einfache, ideale Lösung für Konservierung und Hohlraumschutz und als Spray in der 1-Liter Eurodose und im 5-Liter Gebinde im Shop erhältlich.

Nach ca. 1 Stunde Trockenzeit ist der Klarlack hart genug, um das Abdeckpapier zu entfernen.

…und – Voila! Das Ergebnis kann sich sehen lassen!

Fertig ? Sollten Sie jetzt noch irgendwo kleine Kanten oder Übergänge im Lack finden, dann ist das auch kein Problem: Nach 2 bis 3 Tagen ist der Klarlack komplett ausgehärtet und die Kante wird einfach mit Wasserschleifpapier P2000 sehr vorsichtig abgenommen und anschließend auf Hochglanz poliert.

Natürlich werden Sie jetzt das ganze Auto polieren und mit Hartwachs

Natürlich werden Sie jetzt das ganze Auto polieren und mit Hartwachs