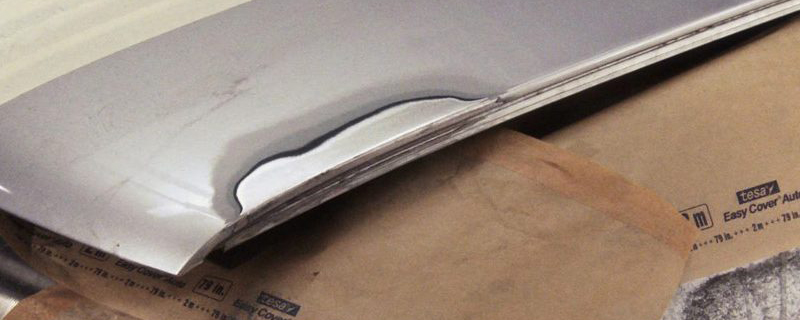

Spot Repair an der Motorhaube

Das Problem: Ein kleiner Rostfleck an einem großen Karosserieteil wie z.B.: der Motorhaube.

Schwierigkeit:

anspruchsvoll

anspruchsvoll

Zeitaufwand:

3h

3h

Kosten:

100€

100€

Ersparnis:

400€

400€

Zusätzliches Werkzeug:

Schleifwerkzeug

Schleifwerkzeug

Profi Tipp: Film – SET: Teillackierung, Spot Repair

Profi Tipp: Film – SET: Teillackierung, Spot RepairUnd so geht`s:

Rost entfernen

Weg mit dem Rost und einfach selber die Karosserie reparieren. Rost, abstehende, lose Blechteile und absplitternde Lackschichten vollkommen entfernen. Trockenschleifpapier – grobe Körnung P 60 – um einen Schleifklotz wickeln und die Roststellen großflächig blank schleifen.

Da darf kein bisschen Rost am Auto mehr zu erkennen sein. Wo vorher Rost war, muss es jetzt blitzeblank glänzen!

angeschliffen.

Danach mit Silikonentferner die Stelle sehr gründlich reinigen.

Da darf kein bisschen Rost am Auto mehr zu erkennen sein. Wo vorher Rost war, muss es jetzt blitzeblank glänzen!

angeschliffen.

Danach mit Silikonentferner die Stelle sehr gründlich reinigen.

Kitten

Auf die blitzblanke, tadellos geschliffene und mit Silikonentferner gereinigte Stelle kann jetzt je nach Notwendigkeit entweder Feinspachtel oder Faserkitt aufgetragen werden.

Und so wird’s gemacht: Kitt auf ein Stück Karton streichen und Härter dazugeben. Die richtige Dosierung ist wichtig. Wenn Sie zuviel Härter verwenden, zieht der Kitt zu schnell an und kann nicht mehr verarbeitet werden, nehmen Sie zu wenig, härtet er nicht aus.

Die Spachtelmasse großzügig und großflächig auf die geschliffene Fläche streichen.

Auf die blitzblanke, tadellos geschliffene und mit Silikonentferner gereinigte Stelle kann jetzt je nach Notwendigkeit entweder Feinspachtel oder Faserkitt aufgetragen werden.

Und so wird’s gemacht: Kitt auf ein Stück Karton streichen und Härter dazugeben. Die richtige Dosierung ist wichtig. Wenn Sie zuviel Härter verwenden, zieht der Kitt zu schnell an und kann nicht mehr verarbeitet werden, nehmen Sie zu wenig, härtet er nicht aus.

Die Spachtelmasse großzügig und großflächig auf die geschliffene Fläche streichen.

Schleifen Nach 30 Minuten ist der Kitt ausgehärtet und Sie können mit grobem Schleifpapier den überflüssigen Kitt trocken abschleifen und so die ursprüngliche Form der Karosserie wieder herstellen.

Alle angrenzenden Teile jetzt vor Sprühnebel schützen!

Dazu nehmen Sie einfach Abdeckpapier und Abdeckband (siehe Film).

Alle angrenzenden Teile jetzt vor Sprühnebel schützen!

Dazu nehmen Sie einfach Abdeckpapier und Abdeckband (siehe Film).

Feinarbeit Gleichen Sie nun die bestehenden Schleifspuren mit Füller aus.

Die Spraydose lange und kräftig schütteln, bis sich die Komponenten in der Dose gut vermischt haben (ca. 5 min). Die kleine Kugel in der Dose muss sich leicht und locker bewegen.

Auf die Dose kommt der Handgriff. Dieser funktioniert wie eine Spritzpistole und erleichtert die Arbeit enorm.

Die Spraydose lange und kräftig schütteln, bis sich die Komponenten in der Dose gut vermischt haben (ca. 5 min). Die kleine Kugel in der Dose muss sich leicht und locker bewegen.

Auf die Dose kommt der Handgriff. Dieser funktioniert wie eine Spritzpistole und erleichtert die Arbeit enorm.

Und wieder Schleifen Schleifen Sie nun die gefüllerten Teile mit Wasserschleifpapier P600.

Die Randzonen wurden mit Schleiffix oder Wasserschleifpapier P2000 ebenfalls großflächig

Nehmen Sie sich Zeit, je gründlicher Sie schleifen, umso besser das Ergebnis.

Die Randzonen wurden mit Schleiffix oder Wasserschleifpapier P2000 ebenfalls großflächig

Nehmen Sie sich Zeit, je gründlicher Sie schleifen, umso besser das Ergebnis.

Profi Tipp:Um beim Schleifen keine Stellen zu übersehen, verwenden Profis Kontrolllack. So erkennt man, sofort, wo bereits geschliffen wurde und wo noch nicht.

Profi Tipp:Um beim Schleifen keine Stellen zu übersehen, verwenden Profis Kontrolllack. So erkennt man, sofort, wo bereits geschliffen wurde und wo noch nicht.Lackieren Ist der Grundfüller aufgetragen, trocken (nach ca. 20 min) und geschliffen, kommt mit dem Lackspray endlich Farbe ins Spiel!

Den Lackspray 5 Minuten kräftig schütteln, bis die Kugel hörbar anschlägt und alles gut vermischt ist. Handgriff aufstecken erste dünne Lackschicht (Klebeschicht) aufsprühen und 3 Minuten ablüften lassen.

Nach 3 Min. die zweite Schicht deckend lackieren.

Bei schwach deckenden Farbtönen kann es nach entsprechender Ablüftzeit notwendig sein, weitere Spritzgänge aufzutragen. Nach jedem Spritzgang den Lack 3 Min. ablüften lassen!

Den Lackspray 5 Minuten kräftig schütteln, bis die Kugel hörbar anschlägt und alles gut vermischt ist. Handgriff aufstecken erste dünne Lackschicht (Klebeschicht) aufsprühen und 3 Minuten ablüften lassen.

Nach 3 Min. die zweite Schicht deckend lackieren.

Bei schwach deckenden Farbtönen kann es nach entsprechender Ablüftzeit notwendig sein, weitere Spritzgänge aufzutragen. Nach jedem Spritzgang den Lack 3 Min. ablüften lassen!

Klarlack – Decklack 2K Klarlack aktivieren und kräftig 2 Min. schütteln.

Eine dünne Lackschicht auftragen, 3 Min. ablüften lassen und zwei deckende Schichten nachlegen.

Gleich anschließend – ohne Ablüften – den Spotblender (Beispritzlack) in leichten Spritzgängen in die Randzonen lackieren. Der Spotblender ermöglicht durch sein ausgezeichnetes Anlösevermögen und gute Polierbarkeit übergangslose Randzonen in der Beispritzfläche.

Eine dünne Lackschicht auftragen, 3 Min. ablüften lassen und zwei deckende Schichten nachlegen.

Gleich anschließend – ohne Ablüften – den Spotblender (Beispritzlack) in leichten Spritzgängen in die Randzonen lackieren. Der Spotblender ermöglicht durch sein ausgezeichnetes Anlösevermögen und gute Polierbarkeit übergangslose Randzonen in der Beispritzfläche.

Polieren Nach mindestens 5 Stunden Trockenzeit kann der ausgehärtete Lack poliert und konserviert werden. Keine Kanten. Keine Ränder. Kein Farbunterschied. Eine einfache, zeitsparende und kostengünstige Reparatur zum Selbermachen.